A Product Development Company | Gaia Sourcing

Design, Prototype, Manufacture

A pioneering product development company

We help innovators and entrepreneurs develop awesome products! We have 20+ years of experience creating products for ISPs, telecommunications companies, data centers and other businesses.

Product development comes from a deep need to solve problems in the market. If you solve a problem, that is where you can bring value to the market. We like to describe ourselves as “Value-Maxer’s”, we help bring the value!

Below is a list of our Product Development Services

Industrial Design

Industrial design helps shape ideas into products.

First thing’s first, we understand the product inside and out. This includes understanding your goals, target market, and technical constraints.

The feasibility of the project relies on the analysis of your request.

Once we ensure your product idea will be manufacturable, we get designing!

Learn More ->

Mechanical Engineering

Mechanical engineering is where things start getting technical.

We solve the technical challenges of product functionality, durability, and production efficiency.

During this stage, our goal is to engineer parts for cost-effective production.

Learn More ->

Electrical Engineering

Electrical engineering is when our experts start designing the circuits.

We help develop reliable, cost-effective, and scalable electronic systems. Our team has expertise in networking hardware, custom IoT devices, and consumer electronics.

Starting with schematic capture, PCB layout, component sourcing, firmware coordination, and hardware testing. Our team optimises every electrical design for both performance and manufacturability.

Learn More ->

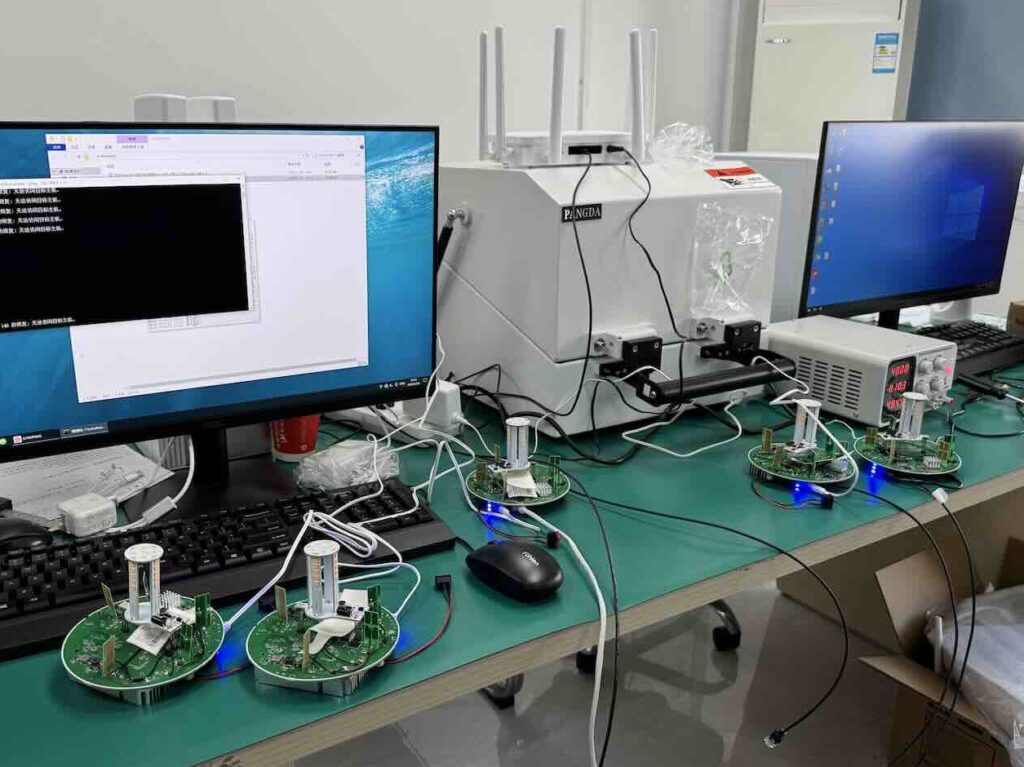

Prototyping

Speed, iteration, and precision are everything when we’re validating a new product.

Prototyping is where ideas get real and where we help you move from design to physical product.

We work with a wide range of prototyping methods. This includes CNC machining, 3D printing, soft tooling, and PCB assembly.

Learn More ->

Packaging Design and Brand Development

Gaia Sourcing builds packaging and branding that speaks to your customer.

Packaging needs to be practical, protective, and represent the best of your brand.

We design all types of packaging, including for retail, e-commerce and bulk-transportation.

Find the balance between creativity and cost-efficiency and design packaging with Gaia Sourcing.

Learn More ->

Contract Manufacturing

We help hardware brands move from prototype to full production — fast and with confidence.

From custom electronics and plastic parts to metal enclosures and printed packaging, we manage it all.

We make sure suppliers follow your specs, hit deadlines, and deliver high-quality results.

Learn More ->

As a product development company, we bridge the gap between design and manufacturing.

Click on a topic above to find out more about a particular service, or click below to chat to an expert!

Speak to the experts today!

New Product Development with Gaia Sourcing

Gaia Sourcing is located in the Greater Bay Area in South China, which is by far one of the worlds largest manufacturing powerhouses. Close to South East Asia, Gaia supports companies seeking alternatives to “Made-in-China”.

The team at Gaia Sourcing has more than 20 years of experience as a product development company. When it comes to development, our aim is not only to identify your competitive edge, but also enhance productivity, foster innovation and reduce cost.

Go from an idea to Mass-production in less than 6 months!

Expertise in

Plastics, Rubbers & Silicone Products

PCB Design and Manufacturing

CE & UL Certified Electronic Products

Telecommunications and Data Center Electronics

Mold Design and Manufacturing

End To End Production Support

Everything you need for a successful product launch

Concept Ideation & Design

Dedicated Team of Experts

Software & Electrical Engineering

3D CAD Engineering & Technical Drawings

3D Printing & Functional Prototypes

Manufacturing & Product Launch Support

The 2 Phases of Product Development with us

Phase 1:

Phase 2:

Your Statement of Work.

It all starts with letting us know your specifications, plans, projections, and requirements.

You provide descriptions, drawings, colors, packaging, delivery, and quality standards.

Together with your team we work to identify the most suitable manufacturing solution for you.

Our Manufacturing Expertise

Next, we leverage our team’s expertise and network of reliable and experienced manufacturers.

We provide services that cover all stages of the product design process, including design, prototype, sampling, molding manufacturing, material suggestions, contract manufacturing, quality control, and so much more.

One of the greatest assets that we provide is monitoring production quality at every step of the way. This is to ensure no corners are cut and you get exactly what you designed, specified and paid for.

As a leading product development company we have built a network of numerous manufacturers and suppliers, and therefore have access to a wide array of production types.

This is why we are able to assist in identifying the ideal manufacturers in a number of different fields, securing the best quotes, and guiding you through every stage of the process.