4.9 based on 100 reviews

Trusted by over 1000 clients

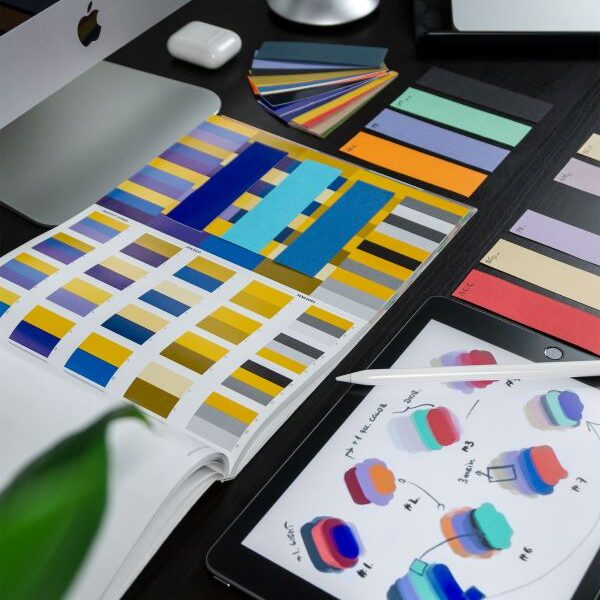

At Gaia Sourcing, we provide comprehensive quality control inspections in China, helping clients verify product quality at every stage from pre-production to final shipment.

Ensuring product quality is critical when sourcing from China. A well-executed QC process helps businesses avoid defects, compliance issues, and costly returns.

Our on-the-ground team ensures your products meet specifications before they leave the factory.

* No prior experience is required, as a skilled agent will take care of all tasks on your behalf.

Skipping quality control inspections can lead to serious consequences, including defective products, costly rework, and shipment delays. Without proper oversight, manufacturers may cut corners on materials, assembly, or packaging, increasing the risk of customer complaints and returns.

Non-compliance with safety regulations can also result in legal issues or rejected shipments at customs. By the time problems are discovered, fixing them is expensive and time-consuming.

Investing in quality control inspections in China ensures your products meet specifications before leaving the factory, protecting your brand and bottom line.

This is just one of the product sourcing company services that we offer at Gaia Sourcing.

In our many years of experience, using a third-party inspection service safeguards our clients’ businesses from costly mistakes.

Independent inspectors provide an unbiased assessment of product quality, ensuring manufacturers meet our specifications before shipment. This prevents defective goods from reaching your customers, reducing returns and protecting your brand’s reputation.

AQL (Acceptance Quality Limit) inspections, like the one we conducted in the above Youtube Video help identify and address quality issues before they escalate. With on-the-ground inspectors verifying every detail. They inspect everything from materials, workmanship, functionality and packaging. You can confidently deliver high-quality products that meet market expectations while avoiding expensive surprises.

Every component of your product affects its quality and customer satisfaction. Without proper verification, you risk receiving products made from substandard materials that fail durability tests, poor workmanship that leads to defects, or inadequate packaging that causes damage during transit.

At Gaia Sourcing, this is a risk we do not take!

Conducting thorough inspections before shipping ensures that our products meet the exact standards that we specify to the supplier before the order has even been placed. This prevents costly rework or returns.

By verifying all of our requirements in advance, we are guaranteed to maintain consistency, protect our supply chain, and uphold our clients’ brand’s reputation in the marketplace.

A proactive approach to quality control is essential. It minimizes risks and keeps operations running smoothly.

Checking raw materials and initial production setup.

Monitoring quality and consistency mid-production.

Ensuring final goods meet specifications before dispatch. e.g. AQL Inspections

Verifying packaging, labeling, and secure shipment loading.

Gaia Sourcing collaborates with top-tier third-party inspection firms like Bureau Veritas, Intertek, and SGS to ensure rigorous quality control.

Our on-site inspections follow international AQL (Acceptance Quality Limit) standards, guaranteeing product reliability.

We don’t just rely on inspectors, we equip them with the specialized tools needed for accurate testing. For example, when a data center client required stainless steel pipes (SS316L) to be verified, the inspector lacked a Sci-Aps XRF Analyzer for material testing.

We needed to be sure that all of the items leaving the factory were of a certain grade and quality. Therefore we found the analyzer (which costs over $25,000 USD) and rented it for the day.

In our experience, there is no way to do quality assurance other than with a hands-on approach.

Transparency is key in sourcing accorss borders. We like to open the gates to the production side by providing real-time production reports and detailed photos and videos.

Our team develops strong on-the-ground relationships with suppliers. This allows us to go beyond standard inspections; we gain deeper insights into their manufacturing processes, material sourcing, and operational practices.

By developing trust with factories, we are given more insight to how the operation is run and we can then uncover potential risks before they escalate. We give you full visibility into your supply chain.

This proactive approach means you’re never in the dark about your products’ quality or the status of an order.

For industries with strict compliance requirements, Gaia Sourcing partners with accredited testing labs to ensure material quality and safety certifications.

But we go a step further—we’ve established our own testing lab to serve as the first line of quality control for technology products.

Before a sample product even leaves China, it will undergo internal testing at our lab in Shenzhen. This ensures that only fully compliant items reach you and prevents costly failures in later testing phases and eliminates wasted time and shipping expenses. If a product doesn’t pass our tests, you’ll know immediately, allowing for faster resolutions and optimized quality assurance.

Gaia Sourcing is a full-service product development and manufacturing company, specializing in everything from idea generation and design to production and market launch.

We partner with startups and established businesses to turn concepts into market-ready innovations with efficiency and expertise.

Headquartered in Shenzhen, China, we operate at the heart of global manufacturing and supply chain innovation.

British Chamber of Commerce South China

Executive Comittee Board Member

CORE PAGES

SERVICES

CONTACT

Tel.: +86 17722845623

Email: [email protected]

Address: 5/F., Building 26, Phase II, Lianchuang Technology Park, Nanwan Street, Longgang, Shenzhen, China

Gaia Premiums Limited © 2025. All rights reserved. Terms and Conditions. Legal Notice.